|

Page 1 |

The Columbia Mine is located in the Shoshone Mining District just south and east of Tecopa California. A number of mines in this area are quite close to each other and some interconnect making this a great area for mine explorers. The mines were worked from the early 1900s through the 1960s. The primary ore was lead and zinc. The inclined shaft into this mine has been burned, so access is now gained through two 150' vertical laddered shafts.

| This is the lowest working level that can currently be reached in

this mine. It is approximately 650 feet from the surface. There is one

additional incline that goes deeper but further exploration is blocked by the

water level. To reach this level requires descending down an inclined shaft, rappelling down two different 150 foot vertical shafts and climbing down through a number of inclined stopes. Getting here is the easy part, climbing back out is the challenge. This mine is not for the timid or out of shape! |

|

| Mines don't often have storage rooms and hauling out garbage

represented an unnecessary expense. Side chambers are often filled with excess

lumber and other mining supplies. If you look closely you will notice an old lunch box sitting on the inverted ore cart. |

|

| This is a small headframe located on the 650 level. It appears that this structure should have supported an inclined shaft, but we were not able to locate it. It may have been back-filled or never actually driven down. |  |

| It's amazing what you find down in these mines. Even if there was an internal combustion engine down here, it seems unlikely to have ever gotten cold enough to freeze the engine. |  |

| One of my fellow explorers looking at the various artifacts left in the mine. With this level being difficult to reach, there are many more artifacts in place than you would expect to see in other, easier to access mines. |  |

| This is the first mine that I've been in that has actual track switches to control the path of the ore carts. |  |

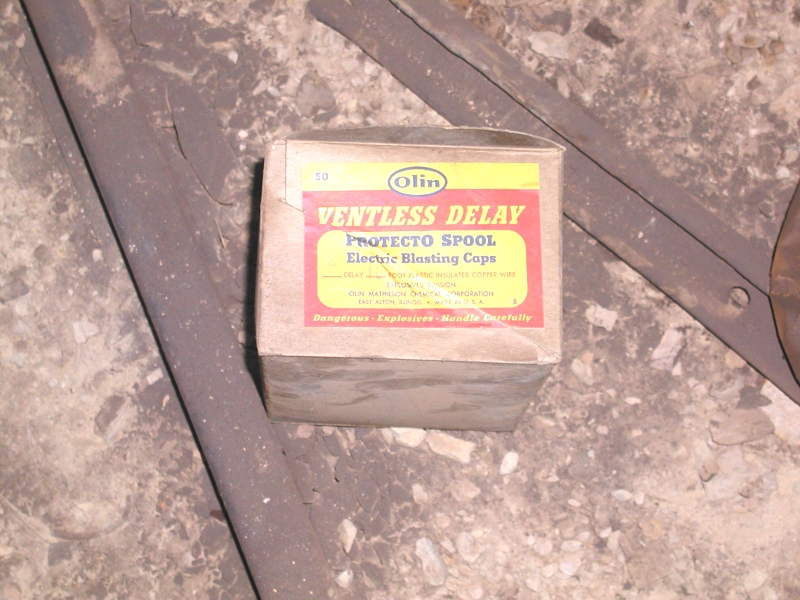

| I always enjoy finding artifacts that show the day-to-day activity within the mine. Wherever there was blasting, there were blasting caps to detonate the dynamite. This box looks relatively modern. |  |

| Air vents and other piping were suspended overhead to leave room for the miners to walk. It looks like some of these air vents were being stored for a future use that never happened. |  |

| Here's one of the guys walking on the rails. What is not shown in

the picture is the 20 foot drop directly below him. The ore carts would have been pushed into this section of the track and dumped into an ore hopper directly below the track. To his left is a "grizzly" that would have screened out the larger rocks from falling down into the hopper. Once the ore was in the hopper it would be loaded into another ore cart on the main inclined shaft and hauled to the surface. |

|

| This insulator would have held the overhead electrical cable. All of the old cable had been stripped out so we couldn't tell if it had been for lights, run fans, or for an electric winch. It might have been used for all of those purposes. |  |

| This is getting to be a rare find. Most of the mine carts have been

removed from mines years ago. Some were taken to other mines for use while

others were taken for people to display in their front yards. This cart would have been used to transport lumber, pipe, or mine track to various parts of the mine. We pushed each other back and forth on this cart to ensure that it is fully operational. |

|

| Making progress on our operational testing of the cart. |  |

| Ultimately the track lead to a chamber with this large headframe in

place. It seems a bit out of place to find such a significant structure so deep

underground. Directly behind the headframe is a chamber where the winch was mounted and the operator would have hauled carts up the incline. This is the incline that is now blocked by the water level. |

|

| This ore cart was used to pull ore and spoil up the inclined shaft.

The ore was then dumped into carts situated on the tracks that we just walked

in on. That ore would then be pushed to the main incline where it was dumped

into the hopper located under the rails. Finally it would be loaded into carts

on the main incline for the trip to the surface. Notice the the wheels on the front of the cart are narrower than the wheels on the back of the cart. |

|

| As the cart was pulled up the headframe, the narrower front wheels

would drop onto the horizontal track while the back wheels would continue up

the incline. That would cause the back of the cart to be raised higher than the

front of the cart and the contents would be poured out into a second ore cart

that was positioned underneath on the level track. It was a very ingenious way of moving ore from one set of carts to another without having to shovel it back and forth. The miners were experts on using gravity to move the ore. |

|

| Another reminder of the day-to-day operation of the mine. Spare parts were hung where they could be grabbed for a quick repair. |  |